Natural gas can either be transported grid-bound via pipelines or liquefied as LNG. In order to increase the energy density, the gas is transported through the pipelines under high pressure (around 80 bar).

Due to the increased energy density, the pipeline can transport a larger amount of energy per unit of time with the same diameter and the same flow rate. To offset the pressure losses during the transport over long distances, the natural gas has to be compressed again every 100 to 200 km. Gas turbines, which are fueled with the pipeline gas, are used in the compressor stations. In the case of the transport over long distances, these stations cause high energy demand for the pipeline. It can be estimated that more than 10 percent of the gas fed into the pipeline is used for the operation of the pipeline to transport natural gas from Siberian sources to Western Europe (distance approx. 5,000 km).

In the past ten years, the submarkets started to integrate due to the increasing use of liquefied natural gas (LNG). In order to transport natural gas in a liquefied form, a transport chain of three elements is required:

- a liquefaction plant to liquefy the natural gas and storage facilities in place located with sea access in the exporting country,

- LNG tankers and

- a regasification plant in the import country in which the liquefied gas becomes gaseous again so it can be fed back into the pipeline system

The more LNG exporters and the more LNG importers share the market, the higher becomes the flexibility of the suppliers but also the demand. If, for example, the European natural gas price is low, the LNG exporter can supply natural gas to Japan, where possibly higher prices can be archived. The increasing use of LNG makes arbitrage trading possible and led to largely adapted prices for natural gas in in different regions of the world. A little less than 20 percent of the European natural gas demand is covered by LNG imports.

Due to the relatively low energy density of LNG the transport via pipeline is expensive as soon as it comes to long distances. This applies not only to the investment cost but also to the operating costs. The transport per toe (per unit of energy) is a lot more expensive than the transport of oil or coal as can be inferred from figure 1.

Figure 1: Comparison of costs for energy transport via long distances (source: BGR Energierohstoffe 2009)

Whether the transport via LNG or via pipeline is cheaper depends on the distance between producer and consumer. In general transportation via LNG is cheaper from a distance of 2,000 to 4,000 kilometers. Still Russian natural gas is transported via pipelines over a distance of up to 5,000 kilometers to Germany. Due to the fact that there is no access to an ice-free sea near the Siberian natural gas fields, it cannot be transported via LNG.

Natural gas storages

Compared to electricity, natural gas is easy to store. As mentioned before the need for storages results from the temperature dependency and seasonality of the gas consumption: The natural gas consumption is six times higher in winter than during summer. For this reason storages are filled during summer and ensure the security of supply during winter.

In principle storages are divided into underground storages and above ground storages. In general underground storages have significant larger capacities than storages above the ground. Underground storages are also distinguished between:

- Pore storages and

- Cavern storages

In Germany salt caverns, exhausted natural gas or oil fields or so-called aquifers are used as natural gas storages.

Cavern storages are created by leaching salt stock (compare figure 2): Water (often sea water) is passed into an unused salt stock which removes the salt from the stock. The saturated water is then returned to the sea and fresh water is again passed into the salt stock. As a result, more and more salt is released from the cavern and the cavern’s capacity increases. This process takes several months to years; finished cavern storages have a height of up to 300 m and a diameter of up to 50 m.

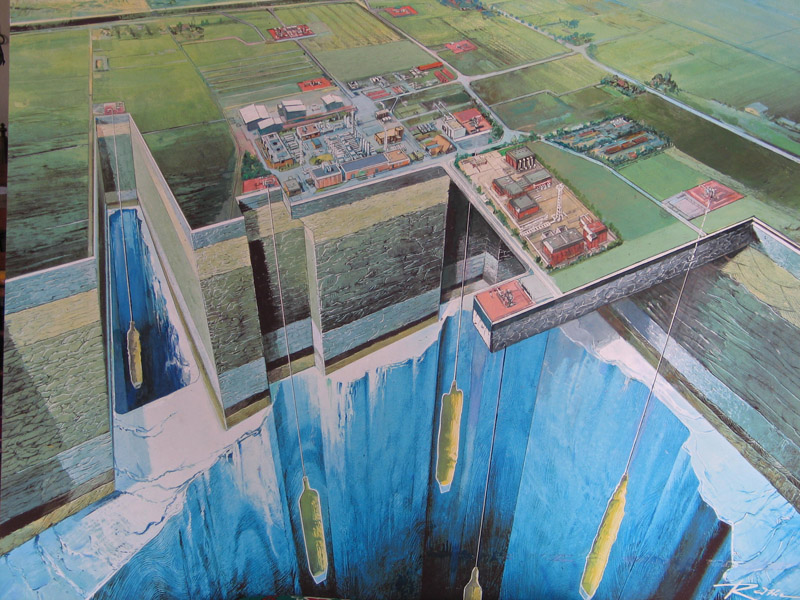

Pore storages, as shown in figure 3 are especially common in southern Germany.There are porous rock layers, which are filled with water. If a gas-permeable layer is present above these rock layers, the water in the space between can be displaced by pressing in natural gas. The porous rock layer can thus be used as gas storage. That requires, however, that the surrounding rock layers are gas-impermeable so that the natural gas cannot escape laterally. The storages are exploited by drillings down up to 1,500 m.

The amount of natural gas that is available for active storage use is known as working gas. The other portion serves to maintain the pressure and remains in the storage during the regular storage operation. This gas cannot be used and is called cushion gas.

Pore storages have a high working gas volume as well as a high cushion gas volume. At the same time their efficiency is low due to the slow feed-in and feed-out process. A complete filling or emptying of the storage takes 40 to 100 days. The properties mentioned (high working gas volumes and slow feed-in and feed-out) predestine pore storages for the use as seasonal storages: They are filled in summer (because natural gas consumption is low in summer, so that the gas is available for the storage) and can help to cover the high demand in winter.

Due to the extreme seasonal nature of the natural gas consumption, natural gas storages and transport infrastructure (pipelines) are also an essential prerequisite to participate in the market and, for example, to act as supplier for end-customers. Access to storage capacities is therefore also regulated and the owners are obliged to allow third-party access to storage capacities without discrimination.

In total the German natural gas storages can absorb more than 20 bn cubic meter of working gas. This corresponds to almost a quarter of the annual German natural gas consumption.

In contrast to the underground storages, above ground storages have a comparatively small volume. They are executed as ball storages or tube storages. They can offset daily fluctuations in natural gas consumption. Also the grid itself can absorb partial fluctuations in natural gas consumption, which happens by fluctuating net pressure (“Netzatmung”). However, since the consumption devices allow only small bandwidth, the use of the grid as storage is limited.